Production

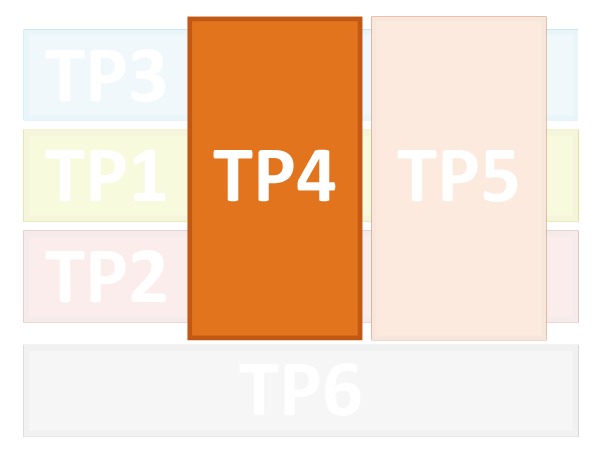

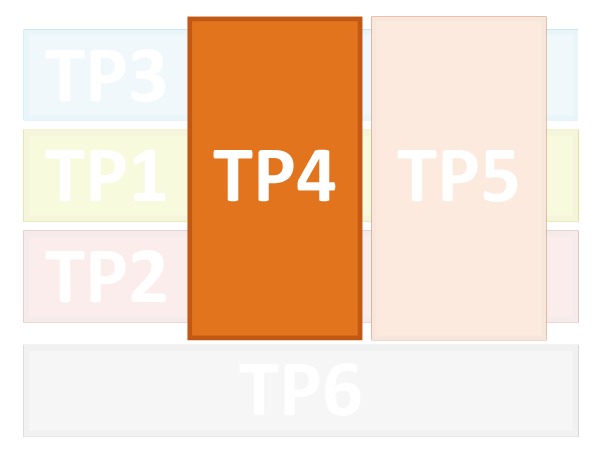

TP4 Use Case 4.1 - AI basesd optical quality control

Use Case: Continental uses an automated optical inspection to detect soldering faults on PCB boards. The aim is to improve the accuracy of the automated optical inspection.

Use Case: Continental uses an automated optical inspection to detect soldering faults on PCB boards. The aim is to improve the accuracy of the automated optical inspection.

Goal: Creating an AI training pipeline on AWS that can be easily migrated to a private cloud.

Approach: The minimal example training pipeline uses machine learning techniques to analyze and classify soldering faults on the PCB and, conversely, improve soldering quality. The goal is to create a model that predicts the class of a specific soldering fault. Continental provides a dataset containing images of soldered PCB circuits and their ground truth. Using EDC, a dataset will be transferred to an S3 bucket, which will then be used to train the model. The model is trained using transfer learning methods and existing models. The trained model is then converted to a web-friendly model and uploaded along with metrics to an S3 bucket. Finally, the model is returned to the customer using EDC. The web model is then loaded into the application to visualize the classification. The training pipeline is designed to be universal and supports various model architectures. The role of the compute provider is assumed by HSO/IMLA, who provide the Gaia-X 4 KI Cloud.

TP4 Use Case 4.2 - Automated optical quality control (AoQ)

Use Case Brief Description: Development of an automatic AI-supported optical quality control of sensors during or after production. Component handling is done with a collaborative robot. Images are passed on to an AI model for quality assessment.

Use Case Brief Description: Development of an automatic AI-supported optical quality control of sensors during or after production. Component handling is done with a collaborative robot. Images are passed on to an AI model for quality assessment.

Specific Use Case: Automated analysis of Lidom glasses from HFL for scratches and dust. Automatic classification into dirty, damaged, and intact.

Challenge: Generating and processing suitable image data. Selection and training of the AI model.

Desired Benefit: Standardized control process, improved error classification, transparency, and traceability.

Where does GAIA-X come into play? GAIA-X comes into play in the communication and exchange of image data between the individual partners. Integration of connectors to ensure secure data flow in the training pipeline.

Possible future scenario: Additional interface between OEM, service provider, supplier.

TP4 Use Case 4.3 - Digital twin inspection methods, generation of data and algorithms

Use Case Short Description: A real-time capable AI-based digital twin is being developed for the assembly of a lens in the optical module of automotive cameras. The aim is to investigate to what extent the Gaia-X ecosystem can offer benefits for the process flow in creating digital twins.

Use Case Short Description: A real-time capable AI-based digital twin is being developed for the assembly of a lens in the optical module of automotive cameras. The aim is to investigate to what extent the Gaia-X ecosystem can offer benefits for the process flow in creating digital twins.

The use case reflects a typical situation in Industry 4.0:

- Creation of a physical twin (DT1)

- Creation of a compact real-time capable model (DT2)

- Usage of the model (DT2) within the production

- Usage of the DT1 and DT2 for product design porpuses

- Actors are: Suppliers (Lens, Curcuit board, Components), Simulation Provider (R&D Engineering Companies), Companies with product domain-and AI- Know-How, Machine- and Product-Manufacturer (Continental)

With Gaia-X

- DT: Data exchange after completion of a confidentiality agreement used in the production process and stored in the production datdase for each product

With Gaia-X

- DT: The process of confidentiality agreement would be automated in a secure way

- Production: Data is only with the supplier. In the documentation of the product manufacturer, only the references on a barcode are available.

Automated & Connected Driving

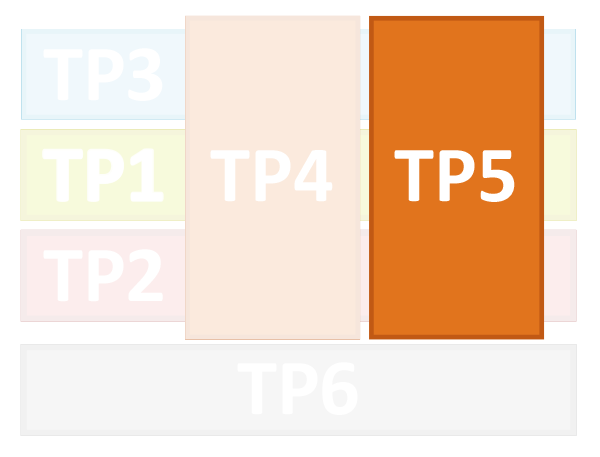

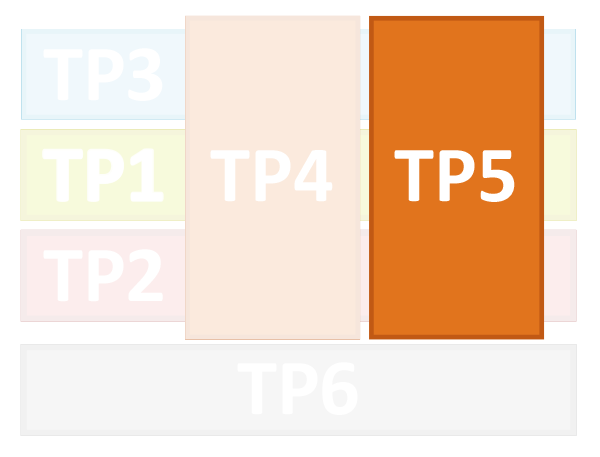

TP5.3 SIEM - Security Incident Event Monitoring

The aim of the USE case is to test a Security Incident Event Management Service (SIEM) as an exemplary USE case. A SIEM captures security-related functions from various entities, evaluates them (analytic) and issues corresponding warnings to the involved Secure Operation Centers (SOC) or Security Incident Response Teams (SIRT).

The aim of the USE case is to test a Security Incident Event Management Service (SIEM) as an exemplary USE case. A SIEM captures security-related functions from various entities, evaluates them (analytic) and issues corresponding warnings to the involved Secure Operation Centers (SOC) or Security Incident Response Teams (SIRT).

Since attacks often cannot be detected by a single instance, it is necessary to combine information from many instances to be able to detect possible threat situations. This combination of information starts with monitoring a single vehicle (host) and combining information from many vehicles. However, the monitoring and analytic must be taken much further than monitoring a single fleet of vehicles from a single manufacturer. Rather, it should enable cross-manufacturer as well as cross-institutional or cross-modal monitoring. This means that it should also be possible to incorporate information from infrastructure providers, mobility services, etc. into the analysis, or to allow them to participate in the analysis.

TP5.3 - Location Spoofing

Introduction: For users of location-based applications, it can be financially rewarding to provide false location information. On mobile phones, manipulating the claimed geolocation is as easy as downloading an app.

Introduction: For users of location-based applications, it can be financially rewarding to provide false location information. On mobile phones, manipulating the claimed geolocation is as easy as downloading an app.

Solution: Assuming that vehicles can "see" each other on the road (e.g. through V2X), we collect observation information and verify the anonymized IDs to confirm whether a vehicle is actually where it claims to be.

Scenario: An Uber/taxi driver is paid based on the distance driven. Illegal behavior: drivers falsify their location, claiming to have traveled a longer distance and thereby receiving more money.

Without Gaia-X: Service providers rely on location data from vehicles for their applications. Provider A with many cars in the area of interest can verify the provided data and detect illegal behavior. Service provider B without many vehicles in the area of interest cannot detect illegal behavior and must rely on the provided data.

With Gaia-X: Through the Gaia-X infrastructure, various partners can use the data space of location data to improve the quality and accuracy of their services. For example, service provider B can now access the anonymized location data from service provider A and successfully detect users' illegal behavior.

TP5 Use Case 5.3 - FSS

The AVF use case "Functional Safety as a Service" focuses on lifetime prediction in the field through condition monitoring to ensure the functional safety of environment-perceiving sensors (here: optical modules) in the automotive sector. Continuous measurement of functionally relevant variables in the field enables the assurance of driving safety using hybrid (physical and data-driven) models. Without the GAIA-X ecosystem, FSS is not feasible, as the use of data from vehicles via the cloud enables various partners to access it in different levels of detail. To generate models for lifetime prediction, reliability measurements are performed in the laboratory. For this purpose, specialized testing facilities are realized. The models extend the digital twins from UC 4.3 for use in the field, both in the vehicle (edge) and in the cloud. Condition monitoring is demonstrated in various forms using the camera systems as a GAIA-X application.

The AVF use case "Functional Safety as a Service" focuses on lifetime prediction in the field through condition monitoring to ensure the functional safety of environment-perceiving sensors (here: optical modules) in the automotive sector. Continuous measurement of functionally relevant variables in the field enables the assurance of driving safety using hybrid (physical and data-driven) models. Without the GAIA-X ecosystem, FSS is not feasible, as the use of data from vehicles via the cloud enables various partners to access it in different levels of detail. To generate models for lifetime prediction, reliability measurements are performed in the laboratory. For this purpose, specialized testing facilities are realized. The models extend the digital twins from UC 4.3 for use in the field, both in the vehicle (edge) and in the cloud. Condition monitoring is demonstrated in various forms using the camera systems as a GAIA-X application.

Added value by GAIA-X in the use case:

- Secure and transparent data exchange between vehicles and cloud

- Regulates access to data through usage rights of involved partners

- Option for using a federated training pipeline

Where does GAIA-X come into play?

- Data exchange (image data, aggregated data, lifetime models) between vehicles and individual partners (OEM, suppliers, end-users) via the cloud

- Inclusion of connectors to define usage rights

- Secure data flow for training pipeline and privacy-compliant use of data from OEMs, service providers, and suppliers

TP5.3 CAPTD - Gaia-X compatible claimhandling in automtotive production transport drives

The application scenario for production and cross-fleet automated driving (highly automated driving) is characterized by the close connection of data from different stakeholders and the traversal of different data spaces or spaces with different ownership structures and regulations that need to be considered in data processing across networks. The basic assumption is that during an autonomous commercial trip within a production facility, an event (e.g. an accident) occurs and this event should be automatically processed within its context immediately, which is only possible through the integration of advanced AI solutions in the network or in the cloud due to the complexity of the event. In this way, all the data necessary for automated decision-making can be brought together, while meeting the requirements of Gaia-X.

The application scenario for production and cross-fleet automated driving (highly automated driving) is characterized by the close connection of data from different stakeholders and the traversal of different data spaces or spaces with different ownership structures and regulations that need to be considered in data processing across networks. The basic assumption is that during an autonomous commercial trip within a production facility, an event (e.g. an accident) occurs and this event should be automatically processed within its context immediately, which is only possible through the integration of advanced AI solutions in the network or in the cloud due to the complexity of the event. In this way, all the data necessary for automated decision-making can be brought together, while meeting the requirements of Gaia-X.

Automated processing of event data and its context using AI (NLP) for immediate automated decision-making. The event data can include audio, text or image material and are analyzed in the data space. In the decision-making process, tasks can be assigned to service employees and machines automatically through a task system. Users can be assigned different user rights and identities to access their personal data in the data space.

The application enables the use of a microservices architecture, which allows for:

- Logical separation of independent components

- Promotes various software engineering properties such as testability, upgradability, or interchangeability of software modules

- Scalability on cloud platforms.

TP5.4 - Online mapannotation & parameterization of AVF function

This use case aims to demonstrate the interaction of various Gaia-X-based services in a real-world autonomous vehicle experiment in the mobility sector. In this application, autonomous driving agents move through a road network guided by intelligent routing services that can respond to dynamic changes in the road network. With a focus on the specific use case, particular attention is paid to ensuring that the underlying architecture allows for broad and scalable adoption of the entire system. The central systems used for the experiment are:

This use case aims to demonstrate the interaction of various Gaia-X-based services in a real-world autonomous vehicle experiment in the mobility sector. In this application, autonomous driving agents move through a road network guided by intelligent routing services that can respond to dynamic changes in the road network. With a focus on the specific use case, particular attention is paid to ensuring that the underlying architecture allows for broad and scalable adoption of the entire system. The central systems used for the experiment are:

• a mapping service that aggregates static and dynamic road data

• a routing service that provides optimal routes based on static and dynamic road data

• an autonomous shuttle as a service user

• an obstacle detection service that can report road blockages

Each of these systems represents a variety of potentially competing commercial services in the Gaia-X ecosystem.

TP5.5 - AVF Validation

This use case deals with the simulation-based verification and validation of automated distributed driving functions (AVF). The basic idea is to create a digital twin of the real vehicle environment using anonymized raw sensor data that can be used to validate different software releases of an AVF function under development. Since the various stakeholders involved in the verification and validation process often distrust each other, in reality, large amounts of data in the PB domain area are usually copied instead of providing the software modules required for verification and validation in the data center or cloud environment where the raw data is stored. This trust issue is intended to be solved by Gaia-X so that the paradigm of "data to code" can be replaced by "code to data".

This use case deals with the simulation-based verification and validation of automated distributed driving functions (AVF). The basic idea is to create a digital twin of the real vehicle environment using anonymized raw sensor data that can be used to validate different software releases of an AVF function under development. Since the various stakeholders involved in the verification and validation process often distrust each other, in reality, large amounts of data in the PB domain area are usually copied instead of providing the software modules required for verification and validation in the data center or cloud environment where the raw data is stored. This trust issue is intended to be solved by Gaia-X so that the paradigm of "data to code" can be replaced by "code to data".